Introduction

In the ever-evolving solar industry, half-cut solar cells have emerged as a high-performance solution promising better efficiency, reduced power loss, and enhanced shade tolerance. With these advantages, they’ve quickly become a standard in modern photovoltaic (PV) system design—whether on rooftops, carports, or utility-scale fields. But as the industry has learned time and again, innovation can introduce complexity. Recent findings from drone-based thermal inspections have raised critical concerns over hot spots developing in half-cut solar cell modules, threatening long-term performance, safety, and return on investment.

This blog explores the structure and benefits of half-cut cells, the faults commonly seen in these systems, and how drone technology is proving essential for identifying early-stage issues that traditional inspection methods often miss.

What Are Half-Cut Solar Cells?

Half-cut cells are standard crystalline silicon solar cells sliced into two equal halves using a laser-cutting process. A typical 60-cell full-cut panel becomes a 120 half-cell module. These cells are then wired in a split module design—with the top and bottom halves functioning as independent electrical circuits, each with its own string of bypass diodes and current pathways.

This design offers several advantages:

- Reduced current per cell string, leading to lower resistive losses

- Better tolerance to shading or partial soiling

- Improved mechanical stress distribution, particularly under wind and snow loads

- Higher power output in real-world conditions, especially for east-west tilt and string inverters

Electrical Advantages of Half-Cut Cells

1. Lower Resistive Losses (I²R)

When current is halved and voltage remains constant, the power lost due to resistance decreases significantly. This translates to higher energy efficiency and improved thermal stability. Over the lifetime of the panel, this small gain in efficiency can result in substantial energy savings, especially in large arrays.

2. Improved Thermal Coefficient

Lower current means less internal heat generation. This contributes to a more favorable temperature coefficient, meaning the panel suffers less efficiency loss as temperatures rise—especially valuable in hot climates.

3. Optimized Performance in Shaded Conditions

Traditional full-cell panels suffer significant power loss from partial shading. In contrast, half-cut cells wired in a split design maintain output from the unshaded half of the panel. This design limits the activation of bypass diodes and maintains power continuity in partially compromised conditions.

4. Greater Durability

Smaller cells distribute mechanical stress more evenly, decreasing the likelihood of breakage or cracking during installation, transport, or thermal cycling.

But Innovation Has a Cost: Common Faults in Half-Cut Modules

Despite their advantages, half-cut modules introduce additional complexity into panel design. More components, interconnections, and solder joints increase the number of potential failure points. Based on recent field inspections and manufacturer data, some of the most common issues include:

1. Microcracks from Laser Cutting

The precision laser cutting process can introduce microscopic edge fractures. While not immediately harmful, these cracks can propagate over time due to thermal expansion, vibration, or mechanical loading—leading to electrical discontinuities or hot spots.

2. Ribbon Interconnect Failures

Half-cut modules use twice as many interconnect ribbons. Over time, thermal cycling can degrade these joints, especially if poor soldering or material fatigue is involved. These failures can cause localized resistance increases, contributing to cell mismatch and overheating.

3. Uneven String Degradation

Since each module is effectively split in two, degradation between top and bottom halves may progress unevenly due to shading patterns, dirt accumulation, or environmental exposure. This imbalance increases the strain on bypass diodes and may lead to internal string mismatch, resulting in performance losses and thermal hotspots.

4. Bypass Diode Fatigue

The split design leads to more frequent activation of bypass diodes, particularly in partially shaded systems. Repeated cycling over time stresses the diodes and can lead to failure, removing protective redundancy and exposing cells to reverse current heating.

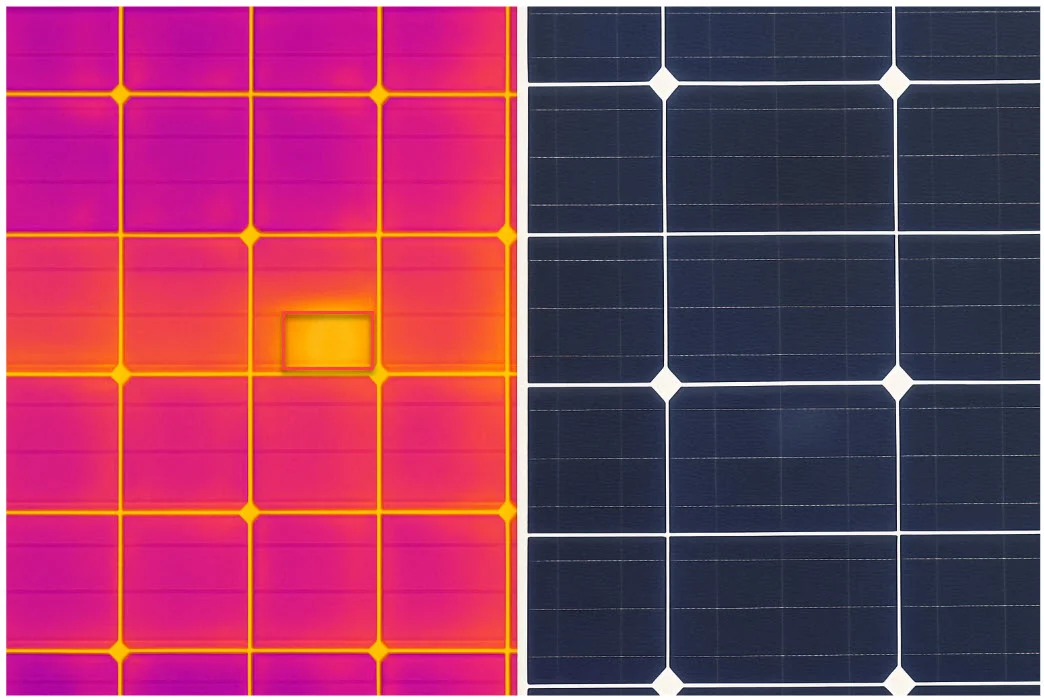

Hot Spots: The Silent Degraders

Hot spots are localized areas on a solar panel where temperature rises significantly above the surrounding surface. These are often caused by resistive heating from cracks, faulty solder joints, or bypass diode failures. In half-cut modules, these can be particularly deceptive due to the small footprint of the half-cells and the narrow thermal margin between normal and problematic behavior.

Undetected hot spots can result in:

- Accelerated degradation of cell materials

- Backsheet melting or browning

- Module warping or delamination

- Reduced power output from voltage drop across hot areas

- Fire risk under extreme conditions

Worse yet, hot spots often develop silently, without any visible damage, until significant efficiency losses occur—or system failure.

Why Traditional Inspection Methods Fall Short

Operators and EPCs often rely on visual inspections, IV curve tracing, and handheld thermal cameras to maintain their PV assets. However, each of these methods has limitations:

- Visual inspections can only detect obvious surface defects—such as broken glass or discoloration—but not internal electrical faults.

- Handheld infrared cameras are useful for small arrays but are inefficient and risky for inspecting large rooftops or utility-scale installations.

- IV curve tracing can identify performance issues on a string level, but it does not pinpoint the exact location or nature of a fault.

- Manual labor costs and safety risks (e.g., fall protection, roof access) make frequent inspections costly and logistically difficult.

These limitations often delay fault detection until system output drops, by which time damage is irreversible or expensive to repair.

Thermal Drones: A Proactive Solution

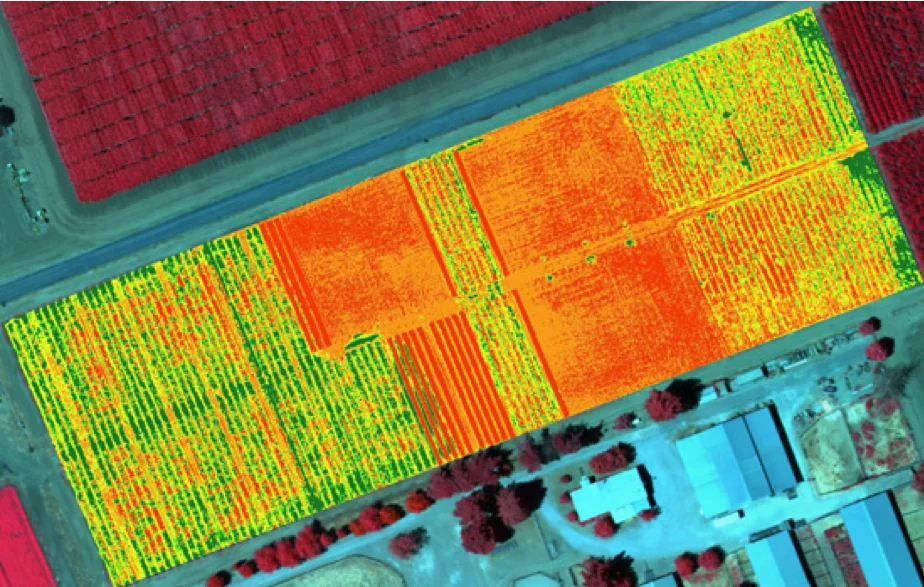

Drone-mounted thermal imaging has emerged as a cost-effective, accurate, and scalable solution to these challenges. With high-resolution infrared sensors and GPS integration, drones can survey entire installations in a matter of hours—capturing precise thermal data that reveals:

- Subtle cell-level heating differentials

- Bypass diode failures and interconnect resistance

- String mismatches, soiling patterns, and shading effects

- Backsheet degradation and delamination areas

In the case of half-cut modules, drones are particularly valuable because:

- The smaller cell footprint makes hot spots harder to detect visually, yet drones can spot minute variations in temperature (as small as 1°C).

- Time-lapse data from drone inspections helps track degradation trends over time.

- Issues such as thermal asymmetry between top and bottom module halves can be captured and flagged for preventive maintenance.

Case Findings: What Drones Are Revealing

Field inspections of large-scale installations have revealed troubling trends. On systems less than five years old, drone thermography has identified:

- Recurring thermal anomalies on half-cut modules where interconnect ribbons were stressed during installation

- Hot spots centered at the laser-cut edges of cells, where microcracks likely initiated

- Modules with full bypass diode dropout, resulting in 33–50% energy loss at the module level

- Clustering of thermal faults in specific array zones, indicating either shading patterns or localized manufacturing issues

In many cases, these modules passed commissioning inspections and only became visibly problematic after extended exposure to field conditions.

Business and Operational Impact

For asset owners and O&M providers, hot spots in half-cut modules represent both a performance risk and a financial liability. The consequences include:

- Increased Levelized Cost of Energy (LCOE) from lost output

- Premature module replacements

- Escalated warranty claims—and in some cases, denials due to lack of documentation

- Potential safety incidents that require shutdown or emergency repairs

- Insurance premium hikes or liability exposure

Thermal drones offer a preventive strategy to mitigate these risks by enabling:

- Condition-based maintenance instead of reactive service calls

- Automated fault classification and geotagging

- Warranty claim support with timestamped thermal images

- Inspection reports that satisfy regulatory, investor, or insurance requirements

Conclusion

The solar industry has embraced half-cut cells as a pathway to higher efficiency, but field experience is proving that complexity comes with risk. As module designs grow more intricate, so too must the tools we use to monitor them.

Thermal drone inspections are no longer optional—they are foundational to modern solar asset management. These inspections not only uncover hidden threats like hot spots but also provide operators with the actionable data needed to maintain peak performance and system longevity.

As solar continues to scale, staying ahead of faults isn’t just about maintaining output—it’s about preserving trust in the technology itself.